Apogee digitalPrint Link: Bridging the Gap Between Prepress and Digital Printing

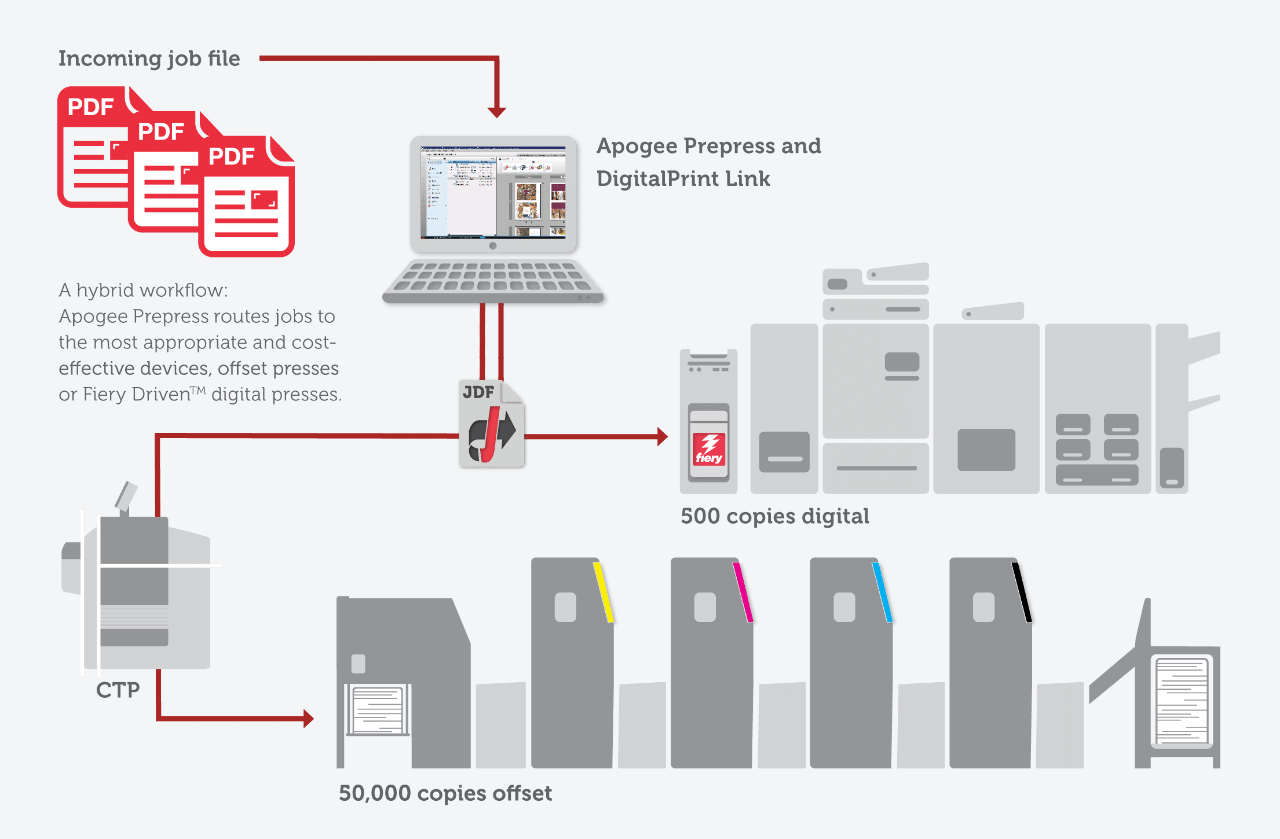

Apogee DigitalPrint Link is a powerful software solution designed to seamlessly integrate digital presses into the Apogee prepress workflow. This integration streamlines production, enhances efficiency, and improves overall print quality. By leveraging industry-standard technologies like JDF/JMF (Job Definition Format/Job Messaging Format), DigitalPrint Link enables printers to manage the entire production process, from prepress to digital output, within a single, unified interface.

Core Functionality

At its core, Apogee DigitalPrint Link facilitates the following key functions:

Automated Job Submission: DigitalPrint Link automates the submission of jobs from the Apogee prepress system to compatible digital presses. This eliminates manual intervention, reduces the risk of errors, and accelerates production time.

Benefits of Using Apogee DigitalPrint Link

The implementation of Apogee DigitalPrint Link offers numerous benefits for printing businesses:

Reduced Setup Times: Automated job submission and streamlined workflows significantly reduce the time required to set up and run print jobs on digital presses.

Consistent Color Reproduction: DigitalPrint Link facilitates consistent color reproduction across different jobs and presses, ensuring accurate color representation.

Unified Interface: DigitalPrint Link provides a single, unified interface for managing the entire production process, from prepress to digital output, simplifying workflow management.

Increased Efficiency: By streamlining workflows and minimizing waste, DigitalPrint Link helps to reduce production costs.

Integration with Diverse Presses: DigitalPrint Link supports a wide range of digital presses, providing flexibility and scalability to accommodate evolving printing needs.

Implementation and Integration

Implementing Apogee DigitalPrint Link typically involves the following steps:

1. Assessment: A thorough assessment of the existing printing environment is conducted to determine the specific needs and requirements of the business.

2. Configuration: The software is configured to integrate with the specific digital presses and other equipment in use.

3. Training: Comprehensive training is provided to prepress operators and press operators on the use of the software and its features.

4. Testing and Validation: Thorough testing and validation are performed to ensure seamless integration and optimal performance.

5. Ongoing Support: Ongoing support and maintenance are provided to ensure the continued smooth operation of the system.

Conclusion

Apogee DigitalPrint Link is a valuable tool for printing businesses seeking to enhance their digital printing capabilities. By streamlining workflows, improving efficiency, and enhancing print quality, DigitalPrint Link empowers printers to meet the demands of today’s fast-paced and competitive market. As digital printing continues to evolve, solutions like DigitalPrint Link will play an increasingly critical role in enabling printers to remain competitive and profitable.

apogee digital print link